In order to maximize efficiency and performance of engines, the quality of fuel plays a significant role. Diesel fuel, with time may be contaminated by impurities like water or sediment. This can cause engine malfunction and expensive repairs. Polishing the fuel is an excellent method to make sure that your engines operate smoothly and combat fuel contamination.

Fuel polishing, also referred as diesel fuel polishing, is a process of removing contaminants and impurities from diesel fuel. Fuel polishing is a service that is performed by experts using the latest technology and equipment to bring fuel to its original state. Fuel polishing increases engine efficiency and decreases the cost of maintenance through the elimination of harmful substances.

Fuel polishing is available in a variety of services to meet the various requirements of businesses that rely on diesel. They employ highly trained technicians who are knowledgeable about fuel systems, and have a comprehensive understanding of the intricate issues that arise from contamination of fuel. With their extensive knowledge and the latest equipment they are able of identifying problems with fuel and apply the proper techniques to polish fuel.

The principal goal of fuel polishing is to remove water as well as sediment, sludge and microbial contamination from diesel fuel. Water can build up in tanks for fuel due to leakage or condensation, leading to corrosion, fuel degrading as well as the growth of bacteria and fungi. Sediment on the other hand results from impurities or degradation in fuel components. These substances can block the injectors and filters as as other crucial components. This could lead to a reduction in engine performance or even a failure.

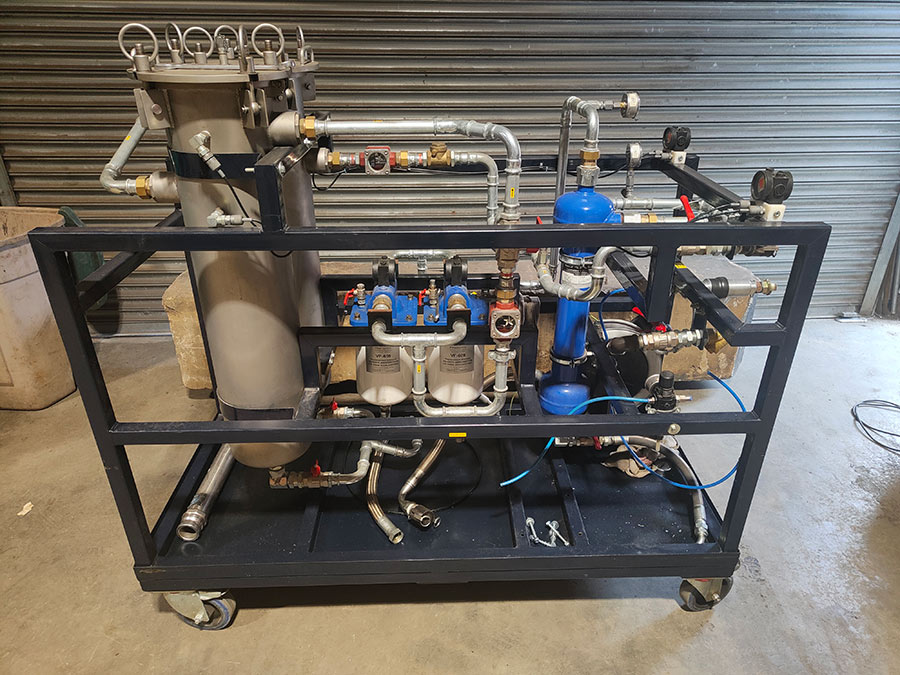

The process of polishing fuel is usually an extensive process. The process starts by conducting a fuel analysis and sample to determine the level of contamination and the most effective option. Technicians use filtering to get rid of the contaminants. These systems utilize various filtering media and techniques to efficiently capture and separate pollutants from fuel, leaving clean and purified diesel.

Regular fuel polishing offers several key benefits. It enhances the quality of fuel and ensures that engines receive regular, clean fuel to allow for optimal combustion. This improves fuel efficiency and performance which results in cost savings and reduced emissions. Fuel polishing also reduces the risk of engine breakdowns as well as damage caused by contaminated gasoline. By removing harmful substances it ensures the integrity of critical engine components, extending their life and decreasing the frequency of repairs and downtime. For more information, click Fuel polishing services

Polishing diesel is a common procedure that can provide many benefits to ensure the quality of fuel. In the first place, it assists to remove contaminants like water, sediments, and microorganisms, which could adversely impact engine performance. The quality of fuel improves dramatically by removing these impurities using the polishing process for diesel. The increased efficiency of combustion will result in a higher fuel efficiency and less emissions. Second, regular diesel polishing lowers the possibility of engine damage by preventing clogging fuel filters, injectors and other crucial components. Regular fuel polishing also makes sure that the fuel storage systems last longer as they prevent the buildup of corrosion and sludge. Regular polishing of diesel fuel can have a number of advantages, including increased engine performance, reduced costs and improved reliability.

Fuel polishing is also modified to meet the requirements of various industries and uses. Fuel polishing is an adaptable solution that can be utilized to prevent fuel contamination in a variety of industries. From backup generators and marine vessels to construction equipment transport fleets, and construction equipment, fuel-polishing offers a range of options to tackle fuel contamination. It is essential for industries that rely on reliable and uninterrupted power supply, as well as industries operating in remote or hostile environments in which the quality of fuel can be a problem.

In summary, fuel polishing is an essential process that helps ensure the purity and high-quality of diesel fuel. It improves engine performance, lowers maintenance costs and extends the lifespan of the equipment by removing contaminants and impurities. By investing in professional fuel polishing can help industries protect their operations, improve performance, and lessen the risks associated with contamination of fuel. Fuel polishing can unlock the potential of diesel fuel, allowing you to drive your business forward.